Since our weekend in Rock Hall we've made a few changes around here. I guess the biggest one is that we've decided NOT to sell our boat. Now, the reason we wanted to sell in the first place was because we had gotten to know this boat pretty well over the past few years and had become aware of a few shortcomings. We thought a center cockpit with an aft master cabin and an in-line galley would really be what we needed for comfort and, of course, it would have to have all the gear we wanted already installed. One thing we found was that every boat is a compromise and there really isn't the "perfect boat" out there. Another little bit of enlightenment was realizing that the market for boats in this price range is really, really dead right now. La Vida Dulce has been on the market for almost a year now with very little interest. Our broker says we should give it another six months. At this point in our lives we just don't have another six months. We have less than two years to go before we retire and head out to chase our dream. It's reached a point on our timeline where going deeper in debt to buy another boat just doesn't make sense anymore. It would push our departure date further off and I don't think we can handle that. I'm already salivating at the thought of leaving in less than two years. As the great Johnny Weissmuller (click here) once said "long wait bad". We want to have both ourselves and the boat ready to go and all our debt paid off. It's about time that we got back on track.

Once we decided to take her off the market we sat down and made a list of what we wanted to change or improve. At the top of that list was comfort. Island Packets are really great boats but if you've ever spent more than fifteen minutes lounging in the salon you'd realize that they aren't built for comfort. Our salon cushions are in good condition but they are hard as a rock. When we gave it some thought we realized that we hardly spend any time at all in the salon and always gravitate into the forward stateroom. What a waste of space! That's supposed to be the living room on our boat. We want the cushions to be more couch-like and maybe have the backs recline a few more degrees. One thing we really liked when we looked at other boats was having one settee divided into two single seats with armrests and a table in between. We figured we could do that with the port side settee and have the back cushion in the center flip down to make a table. That way we still have it for a sea berth or an extra bunk when we have 25 people spend the night. We talked with Cathy Tucker (Catherine's Draperies and Upholstery) and looked at some swatches of material. Cathy gave us a very nice deal on this project, about half of what it would cost getting replacement cushions through the factory. They should be done in a few weeks.

Island Packets have tons of storage but most of it is so deep that things tend to get buried. The port side settee in the salon has three cavernous (24" x 24" x 29") storage areas (lockers) beneath the cushions. The middle one is taken up with an A/C unit, the vacuum cleaner and a thousand pound bag of dog food. The front and back ones are used for canned food and dry goods (sugar, flour, etc). You really need to be organized, which I'm not. Luckily for me my wife is a Project Manager, the epitome of organization. She came up with a good solution for storage of canned and dry goods at "The Container Store". She found these soft, flexible plastic buckets that are just the right size to squeeze four in the bottom of a locker and with the lids on we can get a second level with four more. The buckets have handles too so they're easy to grab and they're not so big that they'd weigh too much, even with cans. We numbered each bucket and listed everything that went into them. We keep a paper copy of that list on top of the buckets so we can find stuff and we have a digital copy on the computer for inventory. Now that's organized! Cool!

We have a number of major items on our list that we're looking into. We'll update here as things move along. In the meantime....

Last Spring we added a chartplotter at the helm and did a custom installation that included re-shaping the stainless steel hoop sticking up on top of the steering pedestal. We laid it back 90 degrees and formed a platform for the swivel mount on our display. This is working out really nice because it keeps the display down low enough to see over when you're sitting at the helm, although it did create a pretty serious problem that I hadn't anticipated. We now have no place to mount our cup holder. I know that doesn't sound like a big deal but let me tell ya......when you're heeled over 15 or 20 degrees and crashing through the waves at 8.5 knots you're gonna need a place to set down your Sangria for a few minutes so you can relight your cigar. It's a problem. I gave it some thought and came up with a design for a cup holder that mounts around the edge of the display platform and holds six glasses or coffee cups. It even has room for a small bowl of peanuts or something. Anyway, I ordered some creme colored Starboard from West Marine, drew out the parts and cut them out with my handy dandy jig saw, using the dock cart as my workbench. I routered all the edges using a 3/16" round-over bit to give it a more finished look. The final piece works out well and can be reached from the helm pretty easily, an important factor.

Since last Summer I've noticed that our bow thruster was down on power. It makes this screeching noise too. We've had several instances where we weren't able to get the bow around into the wind and I didn't remember it being like that before. Being down on power is kinda subtle because we're dealing with a 30,000 pound blob sitting in the water and we're trying to rotate it with a six horsepower electric motor. Not really instantaneous, if you know what I mean. I found this really helpful pdf (click here) that shows step-by-step how to service the motor. It took me a coupla months to get around to it but last Saturday I finally did. I replaced the lube and even modified it by cutting the filler tube and putting in a screw-together connector so it'll be easier to drain next year. I pulled the motor and carried it out to the dock where I blew it out using a can of compressed air. There was quite a bit of carbon dust built up in there! Once I had the motor blown out I removed each of the four brushes and inspected them for damage. They all looked good, had plenty of life left in them and the springs all had about equal pressure. So far, so good. Next I carefully filed out the buildup inside the brush holder to ensure the brushes had free movement. I blew out the whole thing again and reassembled it. With Cheri at the helm while I watched for arcing and sparking, we fired up the engine and ran the bow thruster controls back and forth in short 5 or 10 second bursts. Big difference! That baby was thrusting our bow all over the place! And no screeching either! Woohooo! Total success!

Since last Summer I've noticed that our bow thruster was down on power. It makes this screeching noise too. We've had several instances where we weren't able to get the bow around into the wind and I didn't remember it being like that before. Being down on power is kinda subtle because we're dealing with a 30,000 pound blob sitting in the water and we're trying to rotate it with a six horsepower electric motor. Not really instantaneous, if you know what I mean. I found this really helpful pdf (click here) that shows step-by-step how to service the motor. It took me a coupla months to get around to it but last Saturday I finally did. I replaced the lube and even modified it by cutting the filler tube and putting in a screw-together connector so it'll be easier to drain next year. I pulled the motor and carried it out to the dock where I blew it out using a can of compressed air. There was quite a bit of carbon dust built up in there! Once I had the motor blown out I removed each of the four brushes and inspected them for damage. They all looked good, had plenty of life left in them and the springs all had about equal pressure. So far, so good. Next I carefully filed out the buildup inside the brush holder to ensure the brushes had free movement. I blew out the whole thing again and reassembled it. With Cheri at the helm while I watched for arcing and sparking, we fired up the engine and ran the bow thruster controls back and forth in short 5 or 10 second bursts. Big difference! That baby was thrusting our bow all over the place! And no screeching either! Woohooo! Total success!This update is taking me weeks to get out. I now need to update the update. Tomorrow is Thanksgiving. We have a four day weekend so we're planning to anchor out, either on the Wye (our favoritest haunt now) or maybe down on the Little Choptank. We're planning a non-traditional dinner for Thursday with a pork roast, macaroni and cheese and sweet potatoes. Mmmm, mmmm, mmmm. Last year we went nuts with a more traditional meal and it required spending all day in the galley. By the time we were done with the clean-up we didn't even have time for cigars! This year will be different, fer sure.

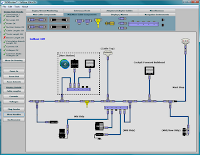

While we're at anchor I have a new project to keep me out of trouble. I'm installing all new instruments at the helm and also below at the Nav Station. They'll get their power and talk back and forth with each other over a single cable system called NMEA 2000 and it all ties in with the MFD (multi-function-display) at the helm. This weekend I'll be installing the backbone cable for that so when my instruments come in next week all I hafta do is plug them in. The real beauty of this system is that you can easily add or change out instruments with screw-together connections and one power connection feeds it all. Plus you can monitor tank levels (fuel, water and holding tanks) and get detailed information about the engine and genset. Everything will display and be controlled from the MFD as well as on smaller programmable displays at the helm and Nav Station. This is gonna be soooooo sweet! To think that less than a year ago we used simple analog displays for speed, wind and depth and relied completely on paper charts. We used to get stuck in the mud at least twice a year. Now using sonar we'll be able to see the bottom of the Bay as we grind into that mud. We'll be able to analyze our environment as we sit there in the mud. We'll be able to watch digital read-outs as the engine sucks up mud and overheats. No more surprises! It'll all be instantly updated and displayed in 256 color high resolution! What a wonderful world we live in!